A new pair of suede or leather footwear is an investment in quality materials. It's also an investment that is uniquely vulnerable to the elements.

To protect that investment, a high-performance suede and leather waterproof spray is non-negotiable. The right formula creates a durable, breathable barrier that repels water and stains while preserving the material’s original texture, color, and hand-feel.

The Science of Protecting Porous Materials

Before you can properly care for your footwear, you must understand why certain materials react so poorly to moisture. Suede and leather are natural, porous materials; their unique structures are precisely what make them susceptible to damage without a protective layer.

Let’s examine how moisture compromises untreated suede and leather.

How Moisture Affects Untreated Footwear

Here is a breakdown of the specific risks suede and leather face from water exposure, highlighting why a quality protector spray is essential.

| Material | Primary Risk from Moisture | Resulting Damage |

|---|---|---|

| Suede | Water absorption into its open, napped fiber structure. | Stiffening, fiber matting, and permanent mineral staining. |

| Leather | Leaching of essential natural oils as water evaporates. | Dehydration, brittleness, and cracking, especially at flex points. |

As the table shows, the damage isn't merely cosmetic—it compromises the structural integrity of the material itself.

Why Suede Is Uniquely Vulnerable

Suede is produced from the inner, split layer of the hide, which gives it its signature soft, velvety finish. That texture is composed of countless fine, open fibers. When water makes contact, these fibers act like a sponge, drawing moisture deep into the material.

As the suede dries, the evaporating water pulls the fibers together into dense clumps. The result is irreversible:

- Stiffening: The material loses its soft, pliable hand-feel and becomes hard.

- Matting: The velvety nap flattens and becomes rough, permanently altering its appearance.

- Discoloration: Water often leaves behind mineral deposits, creating dark spots or "tidelines" that are notoriously difficult to remove.

The risks are significant, and the market reflects this. The global fabric protector spray market has grown to USD 1.27 billion, driven by the need to shield delicate materials like suede. Material science tests show that untreated suede can degrade 70-80% faster in wet conditions, and water damage can reduce resale values by up to 50%.

How Moisture Damages Leather

Smooth leather, by contrast, is derived from the outer grain of the hide. It contains natural oils (a process called fatliquoring) that keep it supple and durable. When water penetrates the surface, it binds to these oils. As the water evaporates, it pulls the oils out with it.

This leaching process is a primary cause of premature aging in leather footwear. Without its natural oils, leather becomes dry, brittle, and prone to cracking, particularly along high-stress areas like the toe box.

An effective protector spray forms an invisible, hydrophobic shield over the pores of the leather. This barrier stops water from soaking in but, crucially, remains permeable to water vapor. This allows the material to breathe, preventing moisture from becoming trapped—a condition which can lead to material rot.

This simple, proactive step doesn't just prevent immediate water spots; it preserves the essential oils that are key to your leather's longevity. Of course, accidents happen. Should a stain penetrate the barrier, knowing how to remove shoe stains correctly is the next critical skill.

Protecting your footwear isn't an optional step. It’s a foundational aspect of ownership that safeguards its value, feel, and appearance for years to come.

How to Select a High-Performance Protector Spray

Not all protector sprays are created equal. The difference between a premium waterproof spray for suede and leather and a low-quality alternative lies in the formulation—a detail that can either preserve your footwear or damage it permanently.

The best sprays use advanced polymer technology to create a flexible, breathable shield over the material. This forms a microscopic matrix that is fine enough to block water droplets from entering but open enough to allow water vapor (perspiration) to escape. This is essential for the long-term health of both leather and suede, as it prevents trapped moisture from degrading the material from within.

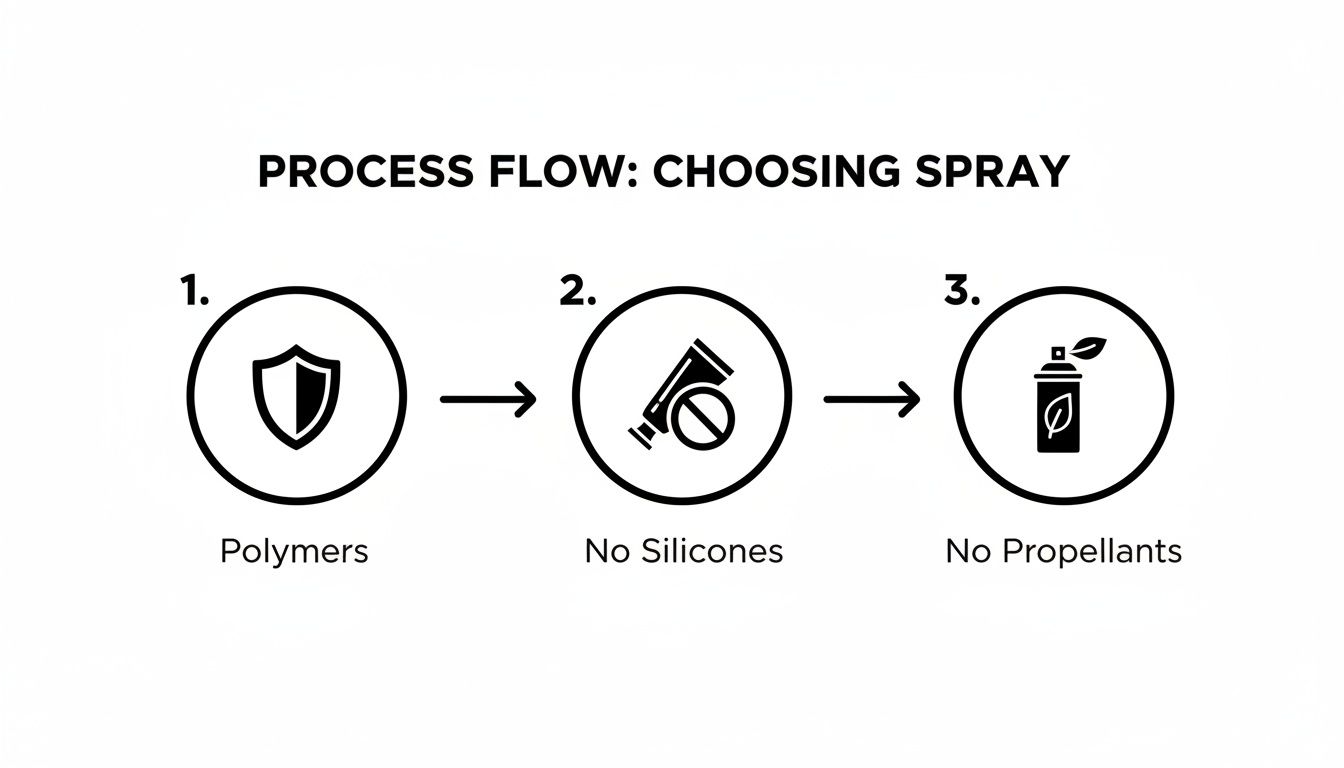

What to Look For and What to Avoid

The objective is to protect the material’s integrity, not just apply a waterproof coating. Many lower-quality sprays are formulated with heavy silicones. While silicone creates a water barrier, it also suffocates the material by sealing its natural pores.

For suede, this is particularly damaging, as it can leave a sticky, shiny film that permanently flattens the delicate nap. For leather, it inhibits the material's ability to breathe, which can trap moisture, accelerate drying, and lead to cracking.

Another consideration is the propellant system. Harsh aerosol propellants can sometimes cause discoloration, especially on lighter-colored suede or nubuck. We recommend formulas that use a non-aerosol pump or propellants known to be gentle on fine materials.

Your footwear deserves a formula that respects its composition. A product that builds a breathable shield without silicone or harsh chemicals is the gold standard for long-term protection.

Making an Informed Decision

The demand for effective shoe care is substantial. The suede leather market was valued at USD 19.19 billion in 2023, yet an estimated 60% of suede owners report water damage as their primary concern. With over 250 million units of waterproof sprays sold annually, selecting the right one is more important than ever.

A high-quality spray can increase water repellency by up to 95% and reduce material degradation in wet conditions by 50%.

To ensure you are selecting a product that delivers professional-grade results, look for these key features:

- Breathable Polymer Technology: This is non-negotiable for maintaining the material's natural structure.

- Silicone-Free Formula: This avoids the risk of clogged pores, sticky residue, and suffocated leather.

- Multi-Material Safe: A versatile spray explicitly tested and proven safe for suede, nubuck, leather, and canvas indicates a well-balanced, high-quality formula.

Choosing a premium protector is an investment in the longevity of your footwear. We developed the Gold Standard Premium Sneaker Protector Spray based on these exact principles. It offers superior protection without compromising the look, feel, or breathability of your favorite pairs.

Proper Application Method for Protector Sprays

Even the best suede and leather waterproof spray is only as effective as its application. A rushed or incorrect application can result in spotting, stiffness, or an uneven barrier that fails to provide adequate protection.

This is the exact, field-tested process for achieving a flawless, durable finish. Proper preparation is the foundation of effective waterproofing. Think of it like painting a wall—one would never apply a fresh coat over dust and grime. The same logic applies here.

Step 1: Prepare the Surface for an Even Coat

Before application, the footwear must be completely clean and dry. Applying a protector over dirt or dust traps those particles against the material, making them nearly impossible to remove later and preventing the spray from properly bonding with the fibers. This creates weak points in the protective barrier.

For materials like suede and nubuck, use a dedicated suede brush to gently brush the surface in one direction. This lifts away loose dirt and raises the nap—the material's soft, velvety texture. Raising the nap is critical, as it allows the spray to coat each fiber individually for maximum protection. For smooth leather, a thorough wipe with a clean, dry microfiber cloth is sufficient.

Expert Tip: Never apply protector spray to damp or recently cleaned footwear. Moisture trapped beneath the protective barrier can lead to discoloration and material degradation. Always allow footwear a minimum of 24 hours to air dry completely after cleaning. For a refresher, our complete guide on how to clean suede sneakers details the correct process.

Step 2: Master Your Spraying Technique

With the shoes prepped, it's time to apply the first coat. The goal is a light, even mist, not a saturated coating. Oversaturation is the #1 cause of dark spots and stiffness, especially on delicate suede.

Follow these steps for a professional application:

- Ventilate Your Workspace: Apply the spray outdoors or in a well-ventilated area to allow propellants and solvents to dissipate safely.

- Maintain Distance: Hold the can approximately 6-8 inches (15-20 cm) from the surface. Too close, and the material becomes saturated; too far, and the spray may dry before reaching the shoe.

- Use Sweeping Motions: Do not point and spray directly. Begin spraying just before the shoe and sweep in a smooth, continuous motion past the other side. This technique prevents heavy deposits where you start and stop.

- Apply a Light, Even Coat: Cover the entire surface without lingering on any single spot. A consistent mist is far more effective than one heavy, wet coat.

The spray's formula directly impacts its application.

A formula built on advanced polymers—without silicones or harsh propellants—is engineered to produce a finer, more even mist for superior coverage.

Step 3: The Curing Process: Two Coats and 24 Hours

After the first coat, patience is crucial. Allow the footwear to air dry for at least 30 minutes in a cool, dry place away from direct sunlight. During this time, the solvents evaporate, leaving the protective polymers to begin bonding with the material's fibers.

Once the first coat is dry to the touch, apply a second light coat using the same sweeping technique. This second pass is critical for filling in any microscopic gaps missed during the first application, ensuring a stronger, more uniform shield.

Now for the most critical step: the curing time. Allow the footwear to sit, undisturbed, for a full 24 hours before wearing. This is when the polymer shield cross-links and hardens on a molecular level, creating a durable, breathable barrier that effectively repels water and stains. Skipping this final step results in a weak, under-formed shield that will not provide the intended protection.

Common Waterproofing Mistakes and How to Avoid Them

Even with a premium waterproof spray, a few simple missteps can turn a protective measure into a permanent problem. We have seen countless high-quality shoes compromised by preventable errors. Understanding what to avoid is one thing; understanding why is the key to achieving professional-grade results.

These mistakes are more common than you might think. The fabric waterproof spray market is a USD 1.5 billion industry, yet user error remains a significant issue. Approximately 70% of sneaker damage is moisture-related, often because protection was applied incorrectly. Furthermore, independent tests show that up to 40% of low-cost sprays can cause discoloration.

In contrast, advanced polymer formulas can repel up to 98% of stains and water, extending the functional life of footwear by 200-300% in wet climates. For those interested in the market dynamics, you can read the full analysis of the fabric waterproof spray market.

Spraying on Dirty or Damp Footwear

This is the most critical mistake: applying spray to footwear that is not completely clean and dry. When you spray over dirt or dust, you are sealing those particles under the protective barrier. They become nearly impossible to remove, and the spray cannot bond properly with the material, creating vulnerabilities in the shield.

The same principle applies to dampness. Spraying a shoe that is still wet traps moisture inside, which can lead to water stains, discoloration, and material degradation from within. Always begin with a clean, dry surface.

Applying Too Much Product at Once

When it comes to protector spray, more is not better. Drenching footwear in a single coat in an attempt to gain extra protection is a recipe for disaster, especially on porous materials like suede. This oversaturation is the leading cause of:

- Dark Spots: Excess liquid pools and dries unevenly, leaving permanent dark patches.

- Stiffness: The material’s fibers become clogged and rigid, destroying the soft hand-feel of suede or the supple flex of leather.

- Uneven Finish: A heavy coat often creates a shiny, plastic-like film on the surface.

The correct method is to apply a light, even mist in two separate, thin coats. Never one saturated layer. Patience is paramount for achieving a flawless, invisible finish.

Skipping the Curing Time

Application is only half the process. The protective barrier forms and bonds to the material during the curing process. Many users become impatient, feel that the shoes are dry to the touch, and wear them immediately. This is a significant error.

A quality spray requires a full 24 hours to fully cross-link and bond at a molecular level. Wearing them prematurely exposes a weak, partially formed shield to the elements. The application becomes significantly less effective, leaving the shoes vulnerable. The 24-hour curing period is the final, non-negotiable step.

Knowing When to Test and Reapply

Effective footwear care is not a single event; it is a maintenance routine. Once you've treated your suede or leather with a quality protector spray, the key to lasting protection is establishing a schedule for testing and reapplication.

Before treating any new pair, always perform a patch test. This is a critical step that separates amateurs from professionals and is your primary defense against unexpected discoloration or texture changes. Find an inconspicuous area—the inside of the tongue or along an internal seam—apply a light spray, and let it cure for a full 24 hours. If the material's appearance is unchanged, you are clear to treat the entire shoe.

The Curing Process and How Protection Degrades

After the final application, the 24-hour curing period begins. This is not merely "drying time." On a molecular level, the protective polymers are cross-linking to create a durable, breathable barrier. Rushing this step results in a weak shield.

Once cured, this barrier is not permanent. Friction from walking, the flexing of the material, and general exposure to the elements will gradually abrade the protective layer. Like sunscreen, it is highly effective but requires reapplication to maintain its performance.

A simple water drop test every few weeks is an effective way to check the barrier's integrity. Place a single drop of water on the shoe. If it beads up and rolls off, the protection is intact. If it begins to absorb and darken the material, it is time for reapplication.

Establishing a Reapplication Timeline

There is no single answer for reapplication frequency; it depends entirely on wear. A personalized approach ensures you are not over-applying product or leaving your footwear vulnerable.

Pro Tip: Cleaning your footwear, especially with detergents, can strip away the protective barrier. Always reapply protector spray after any deep cleaning session.

Use this field-tested guide to build your own routine:

-

High-Wear Footwear (3-5 wears/week): For daily drivers, reapply every 4-6 weeks. These pairs endure constant friction and exposure, causing the barrier to degrade more quickly.

-

Moderate-Wear Footwear (1-2 wears/week): For shoes in regular rotation, a fresh coat every 2-3 months is sufficient to protect against unexpected spills or rain.

-

Low-Wear Footwear (Occasional/Seasonal): For special-occasion dress shoes or seasonal boots, a thorough treatment at the start of the season is typically adequate. Reapply mid-season if they see more use than anticipated.

Frequently Asked Questions

Over the years, we have fielded nearly every question imaginable regarding footwear protection. Here are the most common inquiries from our clients and fellow enthusiasts, answered with expert clarity.

Can I Use the Same Protector on Suede and Smooth Leather?

While some premium sprays are formulated for multi-material use, it is imperative to check the product label. A quality multi-material protector is engineered to form a breathable barrier that is compatible with both the open-napped structure of suede and the finer pores of smooth leather.

The issue with many low-cost sprays is their reliance on heavy silicones, which will permanently clog and flatten suede fibers, destroying their texture. For guaranteed safety, only use a premium suede and leather waterproof spray explicitly designated as safe for both materials.

Will the Protector Change the Look or Feel of My Shoes?

When a high-quality protector is applied correctly, there should be no discernible change to the color or texture. You may observe a slight darkening of the material immediately after application, but it should dry back to its original shade once fully cured. This is a hallmark of a superior formula.

If you experience permanent discoloration, stiffness, or a tacky residue, the cause is almost always a low-grade spray formulated with harsh solvents or silicones.

This is precisely why the patch test is non-negotiable. It is a simple, 30-second check that can prevent irreversible damage from an incompatible formula.

How Do I Know If the Waterproofing is Effective?

The test is straightforward. Once the protector has cured for a full 24 hours, use a dropper or your finger to place a single drop of water on an inconspicuous area.

If the application was successful, the water droplet should bead up instantly and roll off without leaving a mark. If the water absorbs into the material or leaves a dark spot, the barrier is incomplete. This indicates the need for another light coat or a more robust protector.

How Often Do I Need to Reapply?

Reapplication frequency depends entirely on how often the footwear is worn.

- For daily-wear items, reapply every 4 to 6 weeks.

- For special-occasion pairs, a seasonal treatment at the start of winter or spring is usually sufficient.

The most critical rule is to always reapply the spray after a deep cleaning. The cleaning process itself strips away the protective layer, requiring a fresh application to restore the barrier.

You invested in quality footwear. It deserves a protector that respects the craft and the materials. Gold Standard delivers a superior, breathable shield that protects without compromise.